In the realm of new construction, government and community organizations often grapple with the delicate balance between their aspiration to craft iconic structures and the constraints of a fixed budget. In pursuit of their visionary goals, an increasing number of communities are embracing the advantages of prefabricated building solutions, leveraging the capacity to replicate traditional materials, furnish durable and efficient construction solutions, and adhere to their timelines.

Harnessing the Versatility of Prefabrication for Aesthetic Excellence

In the domain of civic and community architectural design, the adaptability of prefabrication is a pivotal advantage. Prefabricated building solutions have made significant advancements in recent years, broadening the spectrum of design possibilities. Through the integration of technologies such as Building Information Modeling (BIM), innovative panel production techniques, and an expanding array of colors achieved via blends and stains, they can now manifest virtually any architectural vision that an owner envisions.

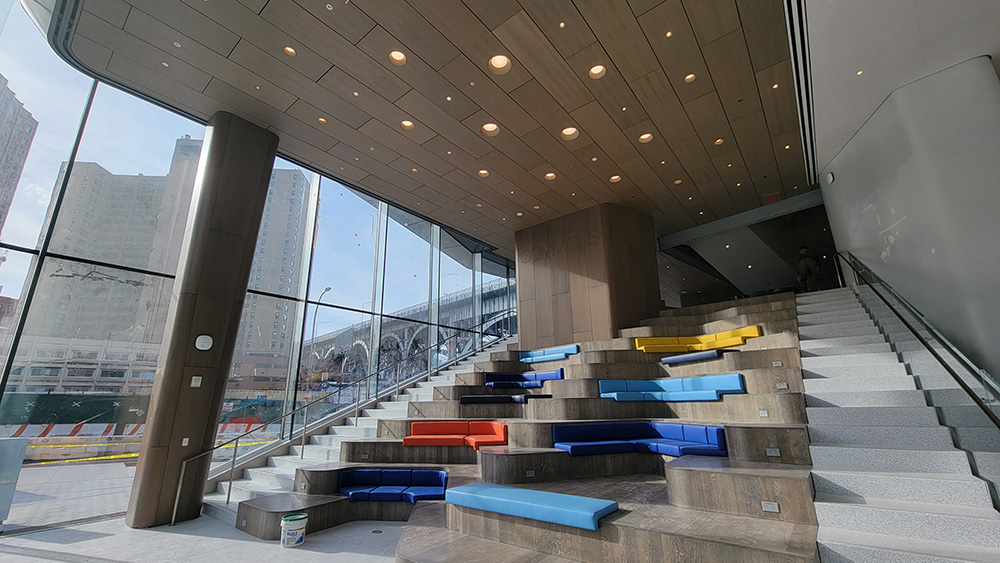

Public entities, mindful of budget constraints, are no longer compelled to settle for unremarkable structures. Instead, prefabrication techniques continue to evolve, offering inventive methods to transform concrete into something far from mundane. The possibilities are virtually boundless—panels can incorporate cast-in thin brick, intricate 3D embellishments, or stone-like finishes. They can replicate the look of stone, wood, metal, or other building materials, offering an array of combination finishes. Unique features such as ledges and cornices are also within reach.

The use of thin brick has gained substantial popularity among government and community entities. A key advantage of prefabrication lies in its ability to harmonize with the aesthetics of existing structures. Conversely, when a modern aesthetic is the objective, prefab designs can incorporate a variety of mixed colors, often followed by a polished or sand-blasted finish on the panels to make a more striking impact. Many government and community organizations also leverage this medium’s versatility to integrate public emblems or imprinted imagery. To complete the contemporary look, prefabricated building systems can incorporate the large glass openings characteristic of modern design.

Understanding the Role of Prefabrication in the Early Design Phase

At the project’s inception, general contractors, architects, and engineers engage the prefabricated manufacturer in a design-assist capacity. This collaborative approach identifies the scope, explores alternatives, provides insights on optimizing panel layouts, and offers options for configuring various finishes. It sets the stage for developing a cost-effective building solution that aligns with the owner’s vision.

During the preconstruction phase, a range of options is typically sketched out and vetted by the design team before being presented to the client, complete with a comprehensive cost breakdown. Subsequently, the prefabrication process continues in tandem with the design team, facilitating design modifications to align with both aesthetic and cost objectives.

When Prefabrication Proves Prudent

The key lies in panelization—the cornerstone of a prefabricated structure. Manufacturers often advocate incorporating multiple prefabricated pieces of uniform size and dimensions while minimizing or eliminating unique features that could inflate the overall construction cost. This approach preserves the architectural intent of the building.

Beyond these considerations, owners are discovering various other merits. In cold climates, prefabricated structures are a favored choice for public buildings, as they allow construction to proceed uninterrupted through the winter months, a stark contrast to traditional construction methods. This rapid construction schedule significantly accelerates project timelines.

Furthermore, prefabricated materials serve the dual purpose of providing structural integrity and insulation in a single product, delivering commendable thermal performance. They also offer the convenience of a single point of contact for the entire building shell, ultimately resulting in lower life cycle costs compared to alternative building materials.

Observing the Trend: Prefabrication’s Rising Prominence

As you stroll through your community, you’ll likely notice a growing trend among government and community entities. They are increasingly turning to prefabricated systems to realize a diverse array of architectural and cost objectives in their building projects. This shift signifies a profound transformation in the way we approach construction, offering a dynamic fusion of creativity and budget-consciousness that is reshaping the urban landscape. Curtis Partition has been at the forefront in the world of prefabrication, diligently incorporating these innovative techniques into our projects for the past decade. Reshaping the landscape of construction with our commitment to excellence and forward-thinking solutions.