Imagine a construction site where robots handle repetitive, labor-intensive tasks, allowing teams to focus on creativity and complex problem-solving. This isn’t science fiction—it’s happening now. Robotics in construction is reshaping the industry, and over the next decade, we can expect even more exciting advancements.

How Robotics Is Changing Construction Today

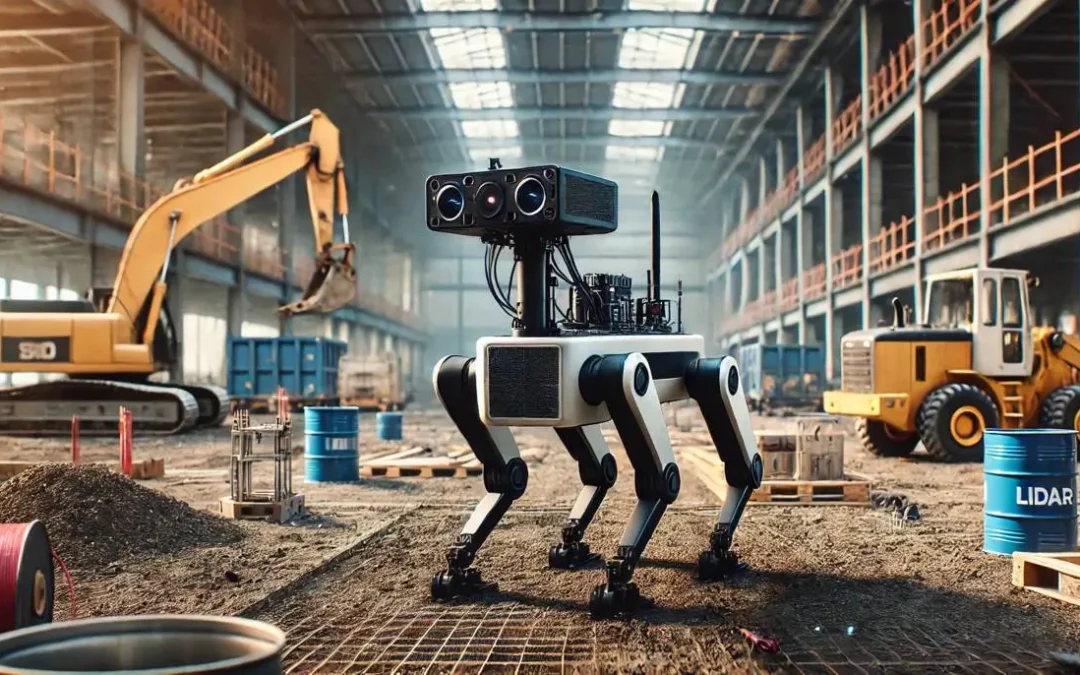

Currently, robotics is transforming construction in significant ways. For example, prefabrication and modular construction processes are more precise thanks to robots that measure, cut, and assemble materials with minimal waste. Additionally, autonomous machinery is streamlining tasks like earthmoving and grading, while robotic systems perform repetitive jobs like painting, bricklaying, and welding.

These innovations bring measurable benefits: improved safety, reduced project timelines, and cost savings. Robots can even handle tasks in hazardous environments, keeping human workers out of harm’s way.

What’s Next for Robotics in Construction?

Think the stuff gong on right now is exciting? Well, the future is even brighter.

Emerging technologies like collaborative robots, or “cobots,” are designed to work alongside human teams, enhancing productivity without replacing jobs. AI-driven robotics will bring adaptive problem-solving to the table, enabling machines to respond to unexpected challenges on-site.

Potential applications include:

- Site surveillance and hazard detection: Robots equipped with cameras and sensors can monitor progress and identify safety risks in real time.

- Advanced 3D printing: Imagine entire buildings constructed layer by layer with 3D printing robots, reducing material waste and opening doors to custom designs.

- Assembly robotics: Autonomous systems capable of constructing structural elements on-site could revolutionize how we approach large-scale projects.

The Challenges Ahead

Despite all of the hype surrounding the industry, adopting robotics isn’t going to come without its hurdles. High upfront costs are a significant barrier for many construction companies, as is the challenge of justifying the return on investment. Additionally, the industry faces a skills gap: workers must learn to operate and maintain advanced robotic systems, which can be daunting for teams used to traditional construction methods.

Integration with existing workflows, like BIM (Building Information Modeling) and prefabrication practices, also requires careful planning to ensure a seamless transition.

What Construction Looks Like in 2035

By 2035, construction sites may look entirely different. Automation will dominate repetitive and labor-intensive tasks, while data-driven construction—powered by IoT (Internet of Things) and robotics—will provide real-time insights for better decision-making.

Robotic systems will also play a critical role in sustainability. By optimizing material usage and energy efficiency, they’ll help reduce waste and promote greener building practices. Safety will see huge improvements as predictive analytics and robotic inspections prevent accidents before they happen.

Curtis Partition: Embracing the Future of Robotics

At Curtis Partition, we’ve always been ahead of the curve. From leveraging prefabrication to streamlining workflows with BIM, we understand the value of innovation. As robotics continues to evolve, we’re exploring how these technologies can enhance our projects and provide better outcomes for our clients.

Our commitment to staying ahead of industry trends ensures we’re not just ready for the future—we’re helping shape an industry that is at an exciting crossroads. Robotics is no longer a futuristic idea; it’s the key to overcoming challenges like labor shortages, efficiency demands, and sustainability goals.

Ready to explore how robotics can improve your construction projects? Contact Curtis Partition today to learn how we’re building the future of construction—one innovation at a time.